|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

Tin Knocker Machinery | TAAG Machinery

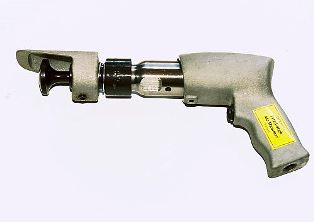

Air Hammers | Sheet Metal Brakes | Cheek benders | Cleatbenders | Combination Machines | Duct Beaders | Edge Notchers | Flangers | Roll Forming Machines | Sheet Metal Shears | Slip Rolls *Quality Machinery at an Affordable Price* Tin Knocker Air HammersTin Knocker Pittsburgh Air HammerCloses up to 16 Ga. Built to exact specifications. Precision machined parts from cast steel and aluminum - heat treated for longevity.

Tin Knocker Sheet Metal BrakesTin Knocker Box & Pan Brake Model 2248 & Model 1648The TK box and pan brakes are made of all steel welded construction, with adjustable truss bars and bronze bushings. The brakes come with removable apron angle and apron insert, permitting .25" (6.35mm) reverse bends in lighter materials. The nose bar is removable as well, and the brakes are equipped with a precise stop rod for repeat bends.

Tin Knocker Straight Brake Model 422

Specifications: Tin Knocker Straight Brake Model 622

Specifications:

Tin Knocker Model 816 & Model 1016 Leaf BrakeTin Knocker offers industrial quality 8' or 10' sheet metal brakes of 16 gauge capacities. Both models include these outstanding

features:

Model 816 Specifications: Model 1016 Specifications:

Tin Knocker No. 1099 Letter BrakeMake can letters and more! Designed to bend sheet metal strips with one or more bent up edges or existing seams. Can also bend 12' of straight sheet metal. Foot operated clamping leaves both hands to handle the material.

Specifications:

Tin Knocker Cheek BendersTin Knocker TK No. 24 Double Sided CheekbenderThis 24 inch, two sided cheek bender is bench mounted and comes ready for service. Consistent bends are a certainty due to the two-way trunnion keeping the bending apron in position at the origin of the bend. Adjusts for 1/4" to 7/8" bends (6.35mm - 22.2mm).

Specifications:

Tin Knocker CleatbendersTin Knocker TK No. 30 CleatbenderThe TK 30 inch cleat former quickly forms uniform drive cleat edges on rectangular duct with no required set up or adjustment. The upper handle forms the cleat and the lower handle opens the work space for easy removal of the metal. This machine is made of heavy cast iron and steel fabrication.

*Shown With Optional Stand Specifications:

Tin Knocker Duct BeadersTin Knocker TK1660 DuctbeaderSave time & money with this 60" x 16 Ga. adjustable beader. Produce SMACNA approved beads in a fraction of the time it takes to cross brake. This heavy duty beader comes with five (5) sets of bead tooling that can be located anywhere over the 60" working length. Tooling, if broken or damaged, is replaceable without the requirement of replacing an entire cross shaft. Beads are adjustable in depth to 3/16" deep. Powered exit support roll to ensure no material hang-up.

Specifications:

Tin Knocker Combination MachinesTin Knocker 724 Combination MachineA multi-purpose deep throat machine, capable of forming many shapes on the sheet metal edge. Comes standard with roll tooling for: Turning, Burring, Wiring, Crimping and Ogee Bead.

Specifications:

Tin Knocker FlangersTin Knocker 20 Ga Manual FlangerPuts 7/32" flange on elbows and other radius fittings. Bench mounted, there is no gauge to set, and requires no special tools.

Specifications:

Tin Knocker Edge NotchersTin Knocker 20 Ga Edge NotcherRound surface edges for collars and end caps Specifications:

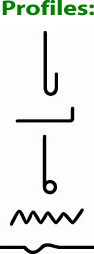

Tin Knocker Slip RollsTin Knocker TK2236 Manual Slip RollTin Knocker rolls are among the strongest in the industry. Precision machined and ground from high carbon steel, these rolls come with wiring grooves, enclosed gear box, and slip roll lift lever. Stand is optional. *Shown With Optional Stand Features: Tin Knocker Roll Forming MachinesTin Knocker TK16GAPitts Pittsburgh Roll Forming MachineThe 16 gauge Pittsburgh Lock machine has 7 forming stations with 2 forming positions. One position forms the Pittsburgh Lock, while the outboard position has the ability of forming a number of other profiles, to include: Acme, Drive Cleat or 4 in 1 rolls (3/16” Right Angle Flange, 7/16” Right Angle Flange, Standing Seam and T-Connection. You don’t pay extra for the choice of opposing rolls, either. You get your choice of rolls opposite the Pittsburgh rolls. Specifications:

Tin Knocker TK24GAPitts Pittsburgh Roll Forming Machine With Stand & FlangerPortable rollformer for 24 gauge and lighter material. It is available with power flanging attachment and is perfect for field use. Includes an all steel stand. Specifications: Note: When shipping, rollformer will fit inside stand

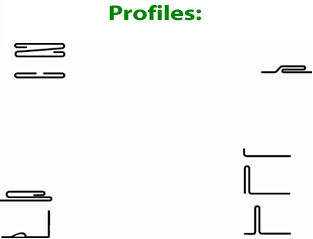

Tin Knocker Fourplex Roll Forming MachineThe Tin Knocker Fourplex is configured with S & Drive down the center and choice of either Male & Female Button Lock or 3 in 1 and Pittsburgh Rolls, this machine comes standard with S & Drive Slitter to turn scrap into useful product. Features:

Specifications:

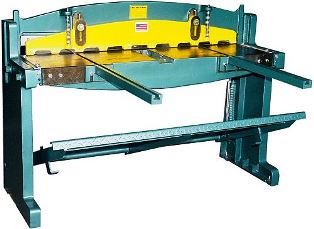

Tin Knocker ShearsTin Knocker TK1652 Foot ShearThe Tin Knocker 1652 foot treadle operated squaring shear includes precise gauging and hold downs for shearing accuracy. This shear is easy to operate. Comes with 25" scaled back gauge. Specifications:

Return to the New Machinery Page Return to the Home Page

|

||||||||||||||