|

Used Machinery

ALL Used

Machinery

Used

Air Compressors

Used Autobrakes / Sheet Metal Folders

Used Bar Folders

Used

Sheet Metal Brakes

Used Cheek Benders

Used

Cleat Benders / Cleat Folders

Used

Clincher / Fasteners

Used Coil Lines

Used Corner Inserter Machines

Used

Crimping / Beading / Rotary Machine

Used Drill Press

Used

Duct Beading Machine

Used

Duct Insulation Liner Cutters

Used

Flangers / Flanging Machines

Used

Gorelockers / Elbow Machines

Used Grinders

Used HVAC Accessories

Used

HVAC Duct Insulation Pin Spotters

Used

Ironworkers

Used

Laser Cutting Machines

Used Notching

Machines

Used

Pipe Equipment

Used

Pittsburgh Seamers

Used Plasma

Cutting Machines

Used Press Brakes

Used Punching

Machines

Used

Sheet Metal Rolls

Used Roll Formers

Used

Saws

Used Sheet

Metal Shears

Used

Sheet Metal Slitters

Used

Spiral Machines

Used

Welders

|

Advance Cutting systems | Autofold Coilines

ACS AutoFold-iFold

Advance Cutting Systems is pleased

to introduce the i-Fold duct coil line. The i-Fold

brings an affordable coil line to even the smallest duct fabricator.

For contractors who use Ductmate™, Ward™ or MEZ™

knock on duct connectors, the i-Fold cannot be beaten

- The i-Fold offers most of the functionality

of a conventional coil line with the advantage of a vastly reduced

floor space requirement (6ft 6in x 10ft).

- The i-Fold allows the operator to use standard

coil widths, in multiple gauges up to 16ga, and manufacture

ductwork from a minimum of 5in x 5in.

- The fully hydraulic system is controlled by the AutoFold v8

Control System that has been designed specifically for this

machine. The input is through a dedicated 14in touch screen

controller that utilizes a Windows™ CE platform to run

the AutoFold Standard Software Program.

- The AutoFold Standard Software includes a Jobs Program.

- Ductwork is produced at an average rate of 1 piece every 20

seconds (depending on the size of the duct). The i-Fold retains

the same production rate as the larger AutoFold machines.

- The AutoFold Standard Software includes a Jobs Program.

The i-Fold can produce the following:

- Flat sheet cut to length blanks

- "L" Sections

- "U" Sections

- Fully Wrapped Duct Sections

AF-iFold Secifications:

- 7 Roll Leveller System consisting

of 2 Entrance Drive Rolls, 3 Leveller Rolls & 2 Exit Bead

Rolls.

- Shear Blades, 4 sides, upper and lower, for extended life

- Maximum Working Gauge: 16ga

- Maximum Material Width: 5ft

- AutoFold v8 Controller with full AutoFold Windows™

CE Software including make quick, jobs and self-diagnostics

programs.

- 14in Touch Screen Monitor with fittings, mounted on the left

or right side of the machine.

- One “A” frame coil holder with spindle. (Maximum

coil weight 10,000lbs at 5ft wide)

Return to TOP

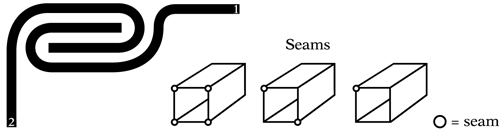

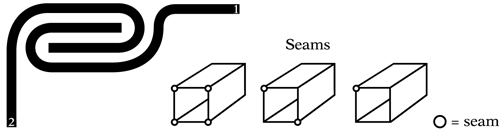

ACS Duct Seam

Closer

Overview:

The Duct Seam Closer is designed to seam rectangular

ducts.

The machine is a solid welded steel construction.

Increases productivity and can be operated with one person.

Includes a 1 year warranty as standard.

The DCS roll-forming machine takes HVAC ductwork

that has previously been formed into “L” or Fully

Wrapped Duct Sections, ot even large duct that has been fabricated

in 4 individual pieces, applies a male and female seam and closes

the seam together quickly, quietly and tightly. Basically, a non-seamed

section of duct goes in one end and a completely closed seam section

of duct comes out the other end. The capacity of the DSC is 26

– 20 gauge.

Specifications for the DSC lock are listed in

the SMACNA HVAC Duct Construction Standards, Second Addition,

1995. The DSC lock is referred to as a Double

Corner Seam or as a Slide Lock Seam. The male and female allowance

of the DSC is similar to that of a male and female Pittsburgh

seam. (ACS recommends that you check with your local inspector

for the approval of the DCS lock). ACS

has many contractors using this seam who will be happy to discuss

their satisfaction with it.

The effectiveness of the Duct Seam Closer is

enhanced when used in conjunction with the AutoFold Coil Line.

The Duct Seam Closer also works well with Ductmate

or Ward knock-on-connectors and can also be used with ductwork

that already has the Drive Clear edge turned over. (The Duct

Seam Closer does not work with the pre-insulated ductwork

or TDC* or TDF* duct connectors).

*TDC is a registered trademark of Lockformer; TDF is

a registered trademark of Engel Industries.

Return to TOP

Return to

the New Machinery Page

Return to the Home

Page

|