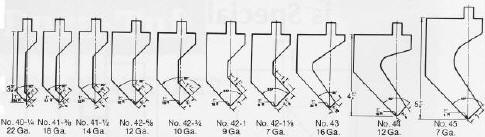

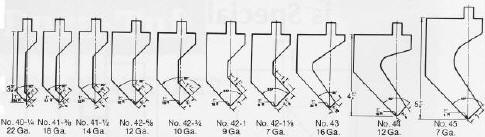

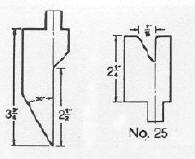

GOOSENECK PUNCHES

Gooseneck punches are used in forming right angle bends, channels

or other special shapes where a straight 90º punch would

interfere. Width of face and depth of cutback are the dimensions

shown. A greater cutback can be furnished but it will reduce the

capacity of the punch. Number 43-44 gooseneck punches are cut

back well beyond centerline allowing a greater return flange.

However, this reduces punch capacity. As the length of the return

flange increases, the width of channel must also increase due

to the taper on the inside of the gooseneck. Number 45 requires

12 inch die space and sufficient ram adjustment to use a general

purpose female die. If press does not have sufficient ram adjustment,

a special height will be required.

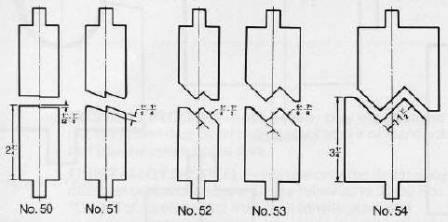

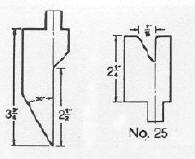

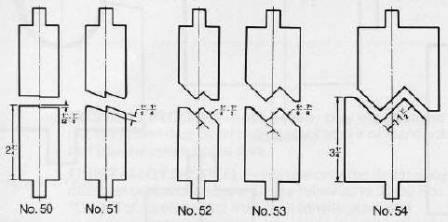

OFFSET DIES

These dies form two 90º bends in one stroke. Note that all

of our offset dies are 1-1/2" wide minimum as the tonnage

required for this type of bend may approach 5 times that required

for a single 90º bend. Dimensions shown indicate amount of

offset from inside to outside of metal thickness. Hat sections

may also be formed if an optional cut-away is ordered on the bottom

die.

Generally speaking, die numbers 50 thru 53 are suitable

for mild steel up to 16 gauge while number 54 may be used with

7 gauge mild steel. However, with certain modifications to angles

and radii the range of these dies may be extended, depending of

course, on press tonnage available.

Many variations of the offset die are also available

including adjustable offset, acute angle offset, open angle offset

with heel, etc. Please submit specs for special die quote.

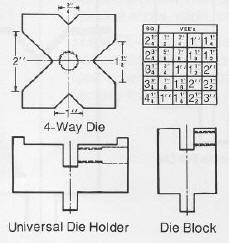

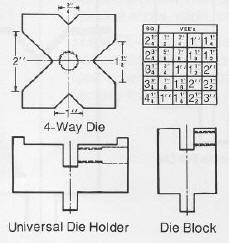

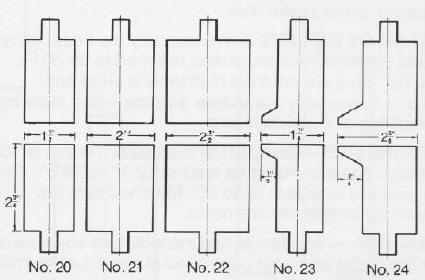

4-WAY DIES & DIE HOLDERS

These dies are useful where different die openings are frequently

required. Any size and configuration of die is available with

the most common being shown in the table at the right.

A Universal Die Holder is recommended for use with the 4-way die

as it allows use of the standard bottom dies without the removal

of the die holder.

Also shown is a Die Block which is used to fill excess die space.

Universal Die Holders and Die Blocks are available in any configuration.

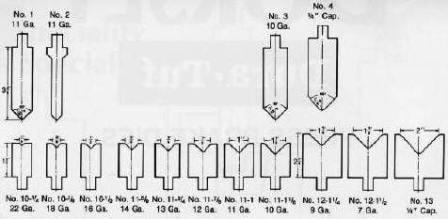

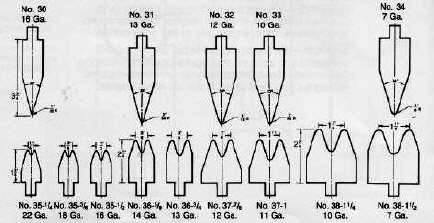

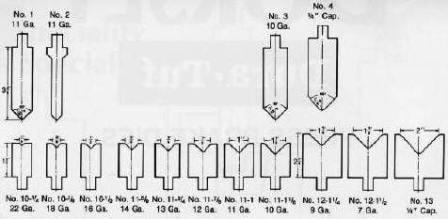

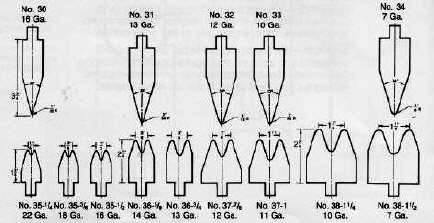

85º - 90º PUNCHES AND DIES

Punches and dies of this type are widely used to make bends of

85º - 90º or greater. By adjusting the ream, angles

greater than 85º - 90º are formed by air bending.

Air bending heavier gauges with these dies minimizes machine load

and material fracture. For the dies shown the die opening is eight

times metal thickness and will produce a bend where the inside

radius is approximately equal to metal thickness. Relief on the

sides of the No. 2 punch permits closer back gauging and longer

returns while maintaining load on the punch shoulders.

NOTE: Angles on die openings are the same as the corresponding

punch.

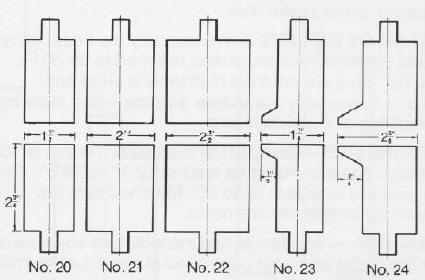

FLATTENING DIES

These dies are used to form a final hemming operation or particular

closure of previously formed acute bends. Both top and bottom

dies have the same number.

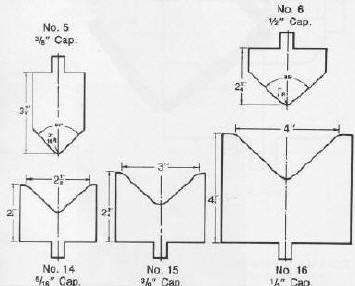

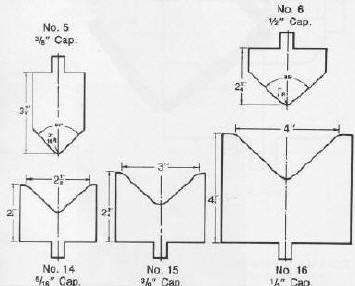

ACUTE ANGLE PUNCHES & DIES

Acute Dies are the most universal type of press brake die, and

are specifically recommended as a starter set. They are used to

make air-form bends from 30º to shallow bends, and also for

the first operation set in hemming. The degree of the formed angle

depends on the depth to which the punch enters the die opening.

All bottom dies cam be furnished with flat tops instead of tapered

sides for increased strength.

NOTE: All bottom die angles are 2º greater than the corresponding

punch.

HEMMING DIES

Hem is formed in two strokes in 18 gauge or lighter mild steel.

Betenbender

Betenbender