|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

Deburring

Ernst Deburring Machines

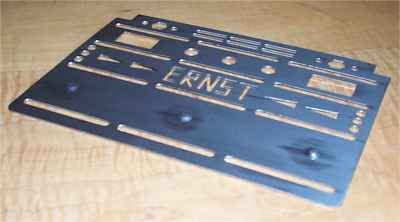

ERNST sheet metal finishing machines feature all the components required to obtain desired finishing results. These components can be flexibly arranged to create the broadest product line offered in the industry. By choosing the desired features, the user is enabled to unite all the functionality he wants to utilize in one machine. Machines are available both for wet and dry finishing. The most commonly applied units are the EM 5/N Wet Deburring System and the EG 3/M Dry Deburring System. The EG 3/M features the most powerful deburring capability for heavy burrs and slag aimed at flame and plasma cutting operations. The entire wet line of ERNST machines has astonishing processing capabilities, such as total deburring of vinyl, galvanized and aluminized coated materials or parts with up forms and distorted parts. The wet machines can be configured to grain, polish and remove oxide layers from laser cut edges for subsequent painting operations.

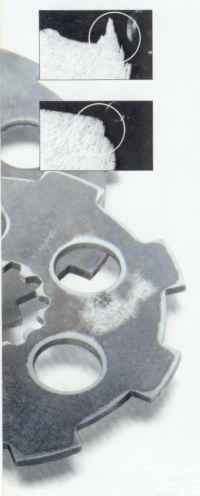

Thanks to the highly elastic surface of the grinding drum, it moulds itself around the edges of every opening of the work piece. Oscillation of the drum ensures the optimal removal of burr and slag no matter which direction the edge points. As you can see in the picture, the material is mainly removed precisely around the edges of a part of any complexity. This “magic” results in superior removal of the burr while at the same time reducing the amount of abrasive consumed. Note the even rounding of the edge in the picture. Additional rounding is achieved by applying steel brushes or even more so by applying abrasive brushes. For possible combinations of finishing media see the list below of machine configurations both wet and dry. Due to the softness of the Ernst Deburring drum’s matrix, thickness and distortion tolerances are easily accommodated, resulting in considerable gains in quality of the work piece and consumable savings. Even if the deburring machine is not used continuously it will deliver great return on investment.

Ernst Deburring Model EM/4N 900

Ernst Deburring Machine Model EM/4N 1400

Ernst Deburring Model EM/5N 900

Ernst Deburring Model EM/5N 1400

Laser-Oxide Removal Machines

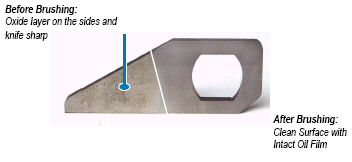

Laser cutting in many ways has become the process of

choice to flexibly manufacture a wide variety of geometries and materials

in sheet metal fabricating. One of the inherent problems presented

by laser cutting with oxygen though has always been the brittle oxide

layer on the surface of the edges. Neither coatings, be it epoxies,

powder or galvanic surfaces are properly bonded to these surfaces.

Already small impacts lead to detachment of the coating in relatively

large areas leading to corrosion and further coating deterioration.

Lissmac Laser Oxide Removal Machine Model SBM 1000-V

Lissmac Laser Oxide Removal | Model SBM 1000-H

Lissmac Laser Oxide Removal Machine - Model SBM 1250-H

Lissmac Laser Oxide Removal - Model SBM 1500-H

Kuhlmeyer Deburring Systems - ZBS Series

Kuhlmeyer Deburring Model ZBS1

Kuhlmeyer Deburring machine Model ZBS2

Kuhlmeyer Deburring Model ZBS3

Kuhlmeyer Debburing Model ZBS4

|

||||||||||||||