|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

Mechanical Sheet Metal shears

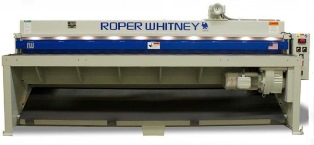

Roper Whitney 10M14 Mechanical Shear

Roper Whitney's 10M14 Mechanical shear is the latest addition to the Roper Whitney line of shears. Manufactured in the United States, the 10M14 Mechanical sheet metal shear is of rugged construction, weighs in at 5,500 pounds, and is powered by a 5 horsepower motor. The 10M14 mechanical shear produces up to 35 strokes per minute. Standard Features of the Roper Whitney 10M14 Mechanical Shear:

Additional Options for the Roper 10M14 Mechanical Shear:

10M14 Mechanical sheet metal shear Specifications:

Roper Whitney Pexto PX1214 Shears

Roper Whitney PX Series Mechanical Shears utilize a low maintenance design, coupled with an array of standard features for an attractive combination of high value and solid performance. The PX1214 incorporates a dual motor design. The dual motor design, of the PX Series, produces accurate distortion free shearing while minimizing machine twist. The system is capable of 45 strokes per minute. The PX1214 is ideal for high volume applications. The PX Series

also includes the unique 2R front operated

back gauge system. This allows the operator to move

the backstop from 0 to 30 inches in approximately 2 seconds

with only two rotations of the handle. A digital readout is

standard for this system. The PX1214 has an

optional “Go-To” 30-inch powered back gauge system

available. The ball screw-driven back gauge provides quick,

accurate cuts. The operator simply inputs a dimension, and then

presses enter, and the gauge automatically positions to that

setting. The Pro Package Includes:

Standard Features Of The Roper Whitney Pexto PX1214 Shear:

Specifications Of The Roper Whitney Pexto PX1214 Shear:

Optional Equipment Available:

Tennsmith LM Series Mechanical Shears

TENNSMITH'S LM Series mechanical shears utilize a simple low maintenance design, coupled with an array of standard features for an attractive combination of high value and solid performance. The LM Series incorporates the unique 2x back gauge system. This allows the operator to move the backstop from 0 to 30 inches in approximately 2 seconds with only two rotations of the handle. An optional digital readout is available for this system. The LM Series shears are standard with four-edge, high carbon, high chrome top and bottom blades , independent, self-leveling hold down feet with neoprene inserts, single, continuous and jog stroke cycles, motor reverse switch, precision-machined table with hand well, dual inch/metric inlaid bed scales and non-metallic gibs. The LM Series will handle 10 - 14 gauge mild steel, 14 - 18-gauge stainless steel and 121 - 145 inches in cutting length. To enhance productivity, optional equipment available for the machine includes: five or ten-foot squaring arm, front support arms, light beam and protractor attachments. Please contact Tennsmith for a complete listing of optional equipment. The LM Series also has available an air operated sheet support system. This system is available in two styles: System-R drops the support material to the rear of the machine; System-F returns the supported material to the front of the machine via a front return chute. Machines Are Standard with 220 Volt or 440 Volt 3 Phase 60 Hz Electrics The LM Series shears are available in a reduced price “Performance Package” configuration. The Performance Package includes: Performance “R” system is for rear return, Performance “F” system is for front return. Available in: LM412, LM610, LM810, LM1014, LM1214 OPTIONS:

|

||||||||||||||