|

Used Machinery

ALL Used

Machinery

Used

Air Compressors

Used Autobrakes / Sheet Metal Folders

Used Bar Folders

Used

Sheet Metal Brakes

Used Cheek Benders

Used

Cleat Benders / Cleat Folders

Used

Clincher / Fasteners

Used Coil Lines

Used Corner Inserter Machines

Used

Crimping / Beading / Rotary Machine

Used Drill Press

Used

Duct Beading Machine

Used

Duct Insulation Liner Cutters

Used

Flangers / Flanging Machines

Used

Gorelockers / Elbow Machines

Used Grinders

Used HVAC Accessories

Used

HVAC Duct Insulation Pin Spotters

Used

Ironworkers

Used

Laser Cutting Machines

Used Notching

Machines

Used

Pipe Equipment

Used

Pittsburgh Seamers

Used Plasma

Cutting Machines

Used Press Brakes

Used Punching

Machines

Used

Sheet Metal Rolls

Used Roll Formers

Used

Saws

Used Sheet

Metal Shears

Used

Sheet Metal Slitters

Used

Spiral Machines

Used

Welders

|

Spot welders | spot welding sheet metal

| Sheet Metal Welding

Tin Knocker

Spot Welder Model TK 1524

TK 1524 Spotwelder Features:

- Foot Operated

- Water cooled (prep)

- Swivel Arms

- Swivel Foot Pedal

- Universal Reversible Double End Arms, 90 & 22 Degrees

- Vertically Adjustable Lower Arms

- 6 Point Heat Selector

TK 1524 Spotwelder Specifications:

- Capacity: 2 Pieces of 16 Ga. Mild Steel

- Arms: 15 KVA x 24" / 1 3/4" Dia.

- Electrics : 230/1/60

- Max. Space Between Arms: 5-11"

- Approx. Weight: 750 lbs.

- 1" Quick Release Tip Holders w/ No. 2 Morse Tape Sockets

,

(2) No. 2 Conical, 5/8" Dia. Alloy Tips

Return to TOP

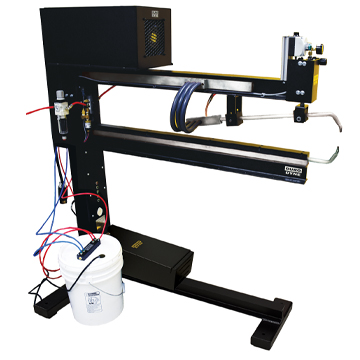

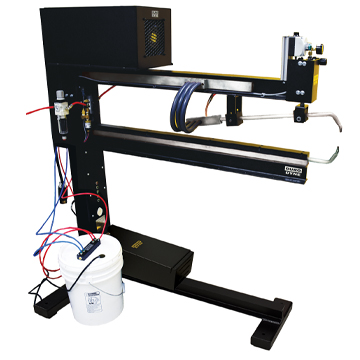

Duro

Dyne BAW5 Spot Welder

The BAW Free Standing Spot-Welding Machine

will weld metal from 30 gauge to 11 gauge. It features a specially

designed transformer and features a pump that cools the welding

tips so there are no burning hazards. The BAW

is an efficient but powerful resistance welder designed specifically

to do the job of spot welding steel in configurations most usually

encountered during sheet metal duct applications.

DEEP THROAT

The 5 foot throat of the BAW allows you to weld

large sheets with minimal movement of material. One man can now

do the job that previously required two. In

addition, the low profile bottom arm and tip assembly enables

you to weld pipe and fitting having a cross sectional dimension

as small as 6 inches.

WATER COOLED TIPS

The BAW’s unique water cooling system injects

water into the tip and then continues through the entire arm,

ensuring both the arm and tip assembly will never over heat.

The BAW also come with a simple water cooling

system: Connect the cooling hoses, add water to the pail, then

plug the pump into the receptacle on the back of the BAW.

FOOT SWITCH ACTUATED

The electric foot switch controls electronic circuits which operates

the arms pneumatically. The unit is designed so the operator can

stop the cycle at any time by releasing the foot switch, allowing

the operator to correct any errors.

BASIC ELECTRICAL CONTROLS

Basic Electrical Control are all that is needed to control this

user friendly welder. The electrodes come together and the weld

turns on and then off, and the electrodes release. The only adjustment

needed is adjusting the length of time of the weld, done by turning

a knob. Complicated computers and PLC that can be affected by

noise and inrush from welding are not necessary. The solid state

and the safety controls that are used in this welder have been

proven to be reliable for years in welders

manufactured by Duro Dyne. Should for any reasons repairs do become

necessary field replacement of components can be easily accomplished.

ELECTRICAL:

100 amp service

DIMENSIONS:

Height: 60 inches

Width: 36 inches

Length: 76 inches

Return to TOP

Rocker Arm Type Resistance Spot

Welders Air or Foot Operated

- Heavy duty welder steel frame

- air operated up to 150 KVA

- foot operated up to 50 KVA

- operator selectable single/Double stage foot switch on

AR models

- heavy duty, self aligning pillow blocks with large bearings

that provide positive alignment

- solid copper arms with steel end caps

- multi-Step transformer tap switch

- ejector - type water cooled tip holders

- wide range of standard and optional controls

50 KVA Spot Welder Features:

- rugged welded steel frame

- built in microprocessor control with dual current, dual

weld time, upslope and pulsation.

- digital phase shift weld current adjustment from 20% to

100% for precision welding.

- maintenance free solid state SCR contactor.

- dual voltage 220V-440V/ single phase/60 hertz output welding

transformer

- soft touch control pad with LED functon and value indicators.

- adjustable throat depth on the rocker arm

- speed control adjustment

- two stage electric footswitch with the option to add a

second footswitch for dual current on the air rocker

Return to TOP

Return to the New

Machinery Page

Return to

the Home Page

|