|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

manual Cleat bendersCleat Folders are used for making HVAC sheet metal ductwork. A Manual Cleat Bender is used in making ductwork, to form the Cleat on fabricated piece so Drive Cleat can be attached. The Cleatbender turns a flat edge 180 degrees to prepare it for the Drive Cleat. For each drive turn, there are three handle pulls: the top to start, the bottom handle to almost complete then release the starting position and the top handle again to finish off.

The alternative to a manual cleat bender is a powered cleat bender.

Roper Whitney CB 3020 Manual Cleat BenderThe manually operated Roper Whitney Cleat Bender quickly forms cleat edges and flanges on rectangular ductwork without set-up or adjustment. In seconds, an operator can use the upper handle to form a cleat or flange in a single pass and easily remove it using the lower handle. The Roper Whitney CB 3020 Cleatbenders precision engineered and ergonomic design features stable cast iron beams and end housings with high quality hinges for long life and trouble free operation. The cleat bender shown here is mounted on an optional stand.

Specifications for the Manual Roper Whitney CB 3020 (cleatbender):

Tennsmith Cleat BendersTennsmith's cleat benders are manually operated tools that form uniform drive cleat edges on rectangular ductwork in seconds without set-up or adjustment. The upper handle forms the cleat and the lower handle opens the tool for easy removal of the material. Heavy cast iron and fabricated steel construction provides long life and trouble - free operation. A Tennsmith Cleat Bender can save you time and money.

Specifications for model 18 Tennsmith Cleatbender:

Specifications for model 24 Tennsmith Cleatbender:

Specifications for model 30 Tennsmith Cleatbender:

Tin Knocker TK No. 30 CleatbenderDurable and dependable! The TK 30 inch cleat former has all the features you would expect from a quality machine. Quickly forms uniform drive cleat edges on rectangular duct with no required set up or adjustment. The upper handle forms the cleat and the lower handle opens the work space for easy removal of the metal. Of heavy cast iron and steel fabrication, this machine is built to last!

*Shown With Optional Stand TK 30 Specifications:

|

||||||||||||||

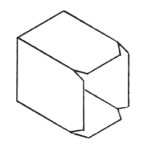

Duct before edge is turned

Duct before edge is turned  Duct

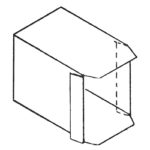

turned 180 degrees, hem on two sides.

Duct

turned 180 degrees, hem on two sides.  Drive

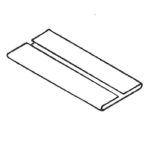

Cleat

Drive

Cleat