|

Used Machinery

ALL Used

Machinery

Used

Air Compressors

Used Autobrakes / Sheet Metal Folders

Used Bar Folders

Used

Sheet Metal Brakes

Used Cheek Benders

Used

Cleat Benders / Cleat Folders

Used

Clincher / Fasteners

Used Coil Lines

Used Corner Inserter Machines

Used

Crimping / Beading / Rotary Machine

Used Drill Press

Used

Duct Beading Machine

Used

Duct Insulation Liner Cutters

Used

Flangers / Flanging Machines

Used

Gorelockers / Elbow Machines

Used Grinders

Used HVAC Accessories

Used

HVAC Duct Insulation Pin Spotters

Used

Ironworkers

Used

Laser Cutting Machines

Used Notching

Machines

Used

Pipe Equipment

Used

Pittsburgh Seamers

Used Plasma

Cutting Machines

Used Press Brakes

Used Punching

Machines

Used

Sheet Metal Rolls

Used Roll Formers

Used

Saws

Used Sheet

Metal Shears

Used

Sheet Metal Slitters

Used

Spiral Machines

Used

Welders

|

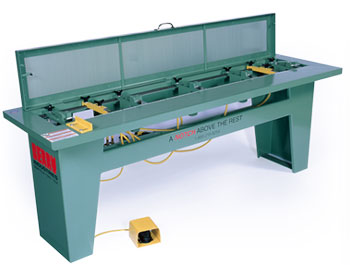

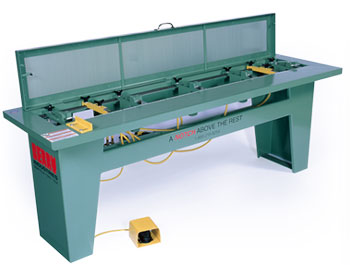

Berry Floor Model Notchers

Berry

Floor Model Notcher

Features of Berry Floor model notchers:

- Easy Installation – All of Berry Notcher floor models

conveniently powered by 110 volt AC (60 Cy.) and will operate

with a minimum 1 HP air compressor at 80-120 PSI.

- 75% Labor Cost Savings – Hand adjustable – no

tools needed – so reconfiguration time is minimal. Cycle

time is one second! Protective screen prevents injury. The

machine operation stops when the screened lid is opened.

- Steel welded frame for the Berry Notchers (floor model)

comes in standard lengths for notching 4', 6', 8' and 10'

lengths of material. Attractive, durable powder coat paint

finish.

- Permanent scales for measuring notch spacing and notch

depth. Assures accuracy and saves time in both set-up and

adjustment.

- 16 Gauge Capacity on the Berry Floor model notchers

- Easy foot-pedal operation leaves operator’s hands

free to handle material, permitting single-operator notching.

Foot pedal activates pneumatic operating mechanism. Cycle

time is one second.

- Individual head control eliminates the need to disconnect

or remove unneeded heads. Each of the notching heads operates

independently with its own air cylinder, operating mechanism

and shut-off valve. By simply turning the shut-off valve,

thus cutting off the air supply, any or all of the heads can

be made in-operable

|