|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

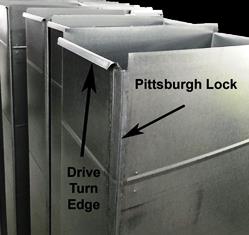

powered Cleat benders / Cleat FoldersCleat Folders are used for making HVAC sheet metal ductwork. Slip and Drive Duct is the most common method of connecting two assembled rectangular duct sections from end to end. S & D Duct requires a Flat S Cleat, which connects the top and bottom, and a drive cleat, which connects the two sides. The drive cleat sides require forming a 180º hem on the end of the sections. Two S Cleats are put on the two straight top & bottom edges of the duct. The Drive Cleat is slid over the two mated 180º pieces to pull them tightly together to complete the connection.

The alternative to a powered cleat bender is a manual cleat bender.

Flagler Hybrid Cleatfolder / Cleat benderThe Flagler hybrid cleatfolder

takes advantage of the best parts of the electric

Specifications for the Flagler Hybrid electric/pneumatic Cleatfolder: Cleat edge ..................... 7/16"

- 1/2" (20 ga. max),

Go To Flagler Machinery Page

Tin Knocker TK No. 30 Power Cleat BenderThe Cleat Bender is another Tin Knocker model designed to increase speed and efficiency in the sheet metal shop. It performs cleat bending operations with precision, safety and ease of performance, yet it only requires one man for operation – even on long or clumsy duct components. No holding, supporting or repositioning of metal pieces is required in cleat forming operations. Solves problems for cleat duct work requiring insulation. Can perform cleat bending operations in the flat when you are producing “L” shaped insulated duct

TK No. 30 Specifications:

Go To Tin Knocker Machinery Page

LION Cleat Bender / Cleat FolderLION closed end cleatfolders (combination cleatbenders and barfolders) are pneumatic.

· Heavy Duty Specifications for the Lion Cleatbenders: Models of Lion Cleat Benders available:

Go To Lion Machinery Page

Roto-Die CB-30 Pneumatic Cleat Bender

Roto - Die ’s CB-30 Cleat Bender is an economical, pneumatic bender for bending cleat on duct and fitting or similar applications that utilize a cleat type connection, up to 20 gauge sheet metal thickness. Unlike the competition, the CB-30 cleat bender requires no electricity, only a compressed air line connection. The stainless steel top resists rust to insure years or service. Unlike competitors machines, the CB-30 has 15 forming fingers, which accommodates more discrete combinations of duct or fitting sizes. Also, with the open ended design, the operator can notch the sheet to make cleats of more than 30” in length by bending in multiple steps. NOTE: The CB-30 Cleat bender bends the cleat in a single thickness of material that has been notched to completely clear the longitudinal seam. The machine cannot bend cleat through multiple thicknesses of material caused by a Pittsburgh seam or Snaplock seam. For proper operation and cleat bending, please insure the seams are notched sufficiently to clear the cleat bend. Wide jaws allow forming ½" Specs:

Go To Roto-Die Machinery Page |

||||||||||||||

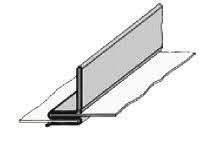

Duct before edge is turned

Duct before edge is turned  Duct

turned 180 degrees, hem on two sides.

Duct

turned 180 degrees, hem on two sides.  Drive

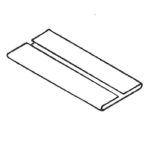

Cleat

Drive

Cleat  Flat "S" Slip Cleat

Flat "S" Slip Cleat Standing "S" Cleat

Standing "S" Cleat