|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

Tin Knocker Machinery | TAAG Machinery

Air Hammers | Bar Folders | Sheet Metal Brakes | Cheek Benders | Cleat Benders | Combination Rotary / Beader / Crimper Machines | Duct Beaders | Flangers & Flanging Attachments | Liner Tables | Notchers | Plasma Table | Punches | Roll Forming Machines | Sheet Metal Shears | Slip Rolls | Slitters | Spotwelders *Quality Machinery at an Affordable Price* Tin Knocker is proud to celebrate two decades of supplying industrial quality, affordable sheet metal working machinery to American contractors (HVAC, Insulation, Sign, Roofing, and more). Conceived from need and built on customer satisfaction, the Tin Knocker brand was established in 1998 with only three models. Today, we offer nearly 50 models, shipping worldwide with plans to expand the line, offering more machines. Family owned and operated since 1986 TAAG Industries Corp., “The Tin Knocker People”, strive to be the leader in low-tech sheet metal working machinery.

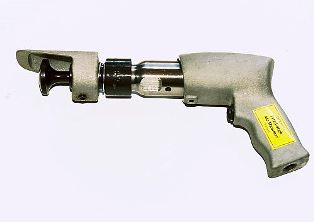

Tin Knocker Air HammerTin Knocker Pittsburgh TK Air HammerCloses up to 16 Gauge sheet metal pittsburgh. Built to exact specifications. Precision machined parts from cast steel and aluminum - heat treated for longevity.

Tin Knocker Bar FolderTin Knocker Model TK No. 30 Bar FolderTin Knocker's affordable, versatile 30" bar folder uses one motion to clamp and fold to a desired angle. The Tin Knocker TK No. 30 bar folder is easy to adjust with an internal back gauge which allows for quick flange width selection.

TK No. 30 Bar Folder Specifications: **Optional stand is also available**

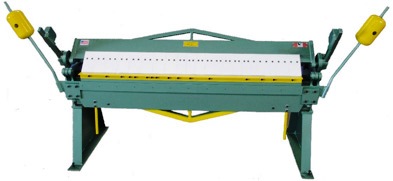

Tin Knocker Sheet Metal BrakesTin Knocker Box & Pan Brake Model TK 2248The TK box and pan brakes are made of all steel welded construction, with adjustable truss bars and bronze bushings. The brakes come with removable apron angle and apron insert, permitting .25" (6.35mm) reverse bends in lighter materials. The nose bar is removable as well, and the brakes are equipped with a precise stop rod for repeat bends.

*Shown With Optional Stand

Tin Knocker Box & Pan Brake Model TK 1648The TK box and pan brakes are made of all steel welded construction, with adjustable truss bars and bronze bushings. The brakes come with removable apron angle and apron insert, permitting .25" (6.35mm) reverse bends in lighter materials. The nose bar is removable as well, and the brakes are equipped with a precise stop rod for repeat bends.

*Shown With Optional Stand

Tin Knocker Portable Brake Model TK 422

Features include: TK 422 Portable Brake Specifications: Tin Knocker Straight Brake Model TK 622

TK 622 Straight Brake Specifications:

Tin Knocker Straight Brake Model TK 816 Leaf BrakeTin Knocker offers industrial quality 8' sheet metal brakes of 16 gauge capacities.

Included Ffeatures: Model TK 816

Specifications:

Tin Knocker Straight Brake Model TK 1016 Leaf BrakeTin Knocker offers industrial quality 10' sheet metal brakes of 16 gauge capacities.

Included Ffeatures: Model TK 1016

Specifications:

Tin Knocker TK Letter BrakeMake channel letters and more! Designed to bend sheet metal strips with one or more bent up edges or existing seams. Can also bend 12 inches of straight sheet metal. Foot operated clamping leaves both hands to handle the material. This machine is perfect for the sign manufacturing industry - Channel Letter Brake.

TK Letter Brake Specifications: Tin Knocker TK 616 Universal BrakeAn incredibly universal hand brake. Featuring box & pan fingers up top and segmented, relocatable bend apron tooling below. Perfect for complex parts to include flange down bends, transverse duct forming & much more. With strategically positioned counter weights this brake makes for easy and smooth manual bending.

TK 616 Universal Brake Specifications: Tin Knocker Cheek BendersTin Knocker TK No. 24 Cheek BenderThis double sided, 24 inch cheek bender can be bench mounted and comes ready for service. Consistent bends are a certainty due to the two-way trunnion keeping the bending apron in position at the origin of the bend. Adjusts for 1/4" to 7/8" bends.

TK No. 24 Cheekbender Specifications:

Tin Knocker Cleat BendersTin Knocker TK No. 30 Cleat BenderThe TK 30 inch cleat former quickly forms uniform drive cleat edges on rectangular duct with no required set up or adjustment. The upper handle forms the cleat and the lower handle opens the work space for easy removal of the metal. This machine is made of heavy cast iron and steel fabrication.

*Shown With Optional Stand TK No. 30 Cleat Bender Specifications:

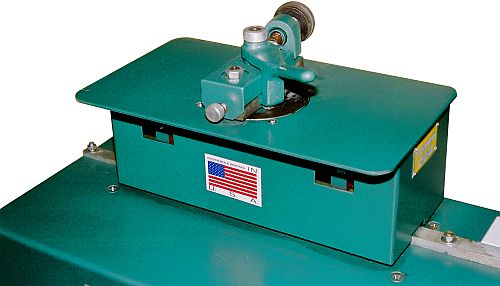

Tin Knocker TK No. 30 Power Cleat BenderUNIQUE, PATENTED DESIGN!!!!! The TK No. 30 Power Cleat Bender is a smooth running, quiet machine that will last a career. Fast and efficient, this machine effortlessly prepares the duct for drive cleats. The machine is strong enough to form the reverse, open hem with a swift wiping action. THIS MEANS LITTLE OR NO SHOCK AND THE MACHINE WILL NOT KILL ITSELF. The TK No. 30 is the only machine in the market with a proven FAILSAFE SYSTEM which protects the machine from damage due to operator error. It’s oversized table promotes safety and improved control of already formed duct sections. US Patent No. US D830,4315 S

TK No. 30 Power Cleat Bender Specifications:

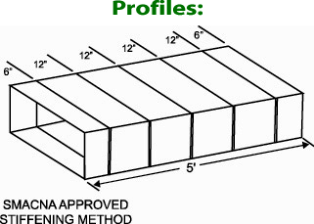

Tin Knocker Duct BeadersTin Knocker TK 1660 Duct BeaderSave time & money with this 60" x 16 Ga. adjustable beader. Produce SMACNA approved beads in a fraction of the time it takes to cross brake. This heavy duty beader comes with five (5) sets of bead tooling that can be located anywhere over the 60" working length. Tooling, if broken or damaged, is replaceable without the requirement of replacing an entire cross shaft. Beads are adjustable in depth to 3/16" deep. Powered exit support roll to ensure no material hang-up. Stop cross breaking ductwork. Use this power duct beader to stiffen your duct. This 60" beader is the best value in the HVAC industry.

TK 1660 Duct Beader Specifications:

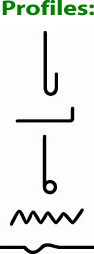

Tin Knocker Combination Rotary MachinesTin Knocker TK 724 Combination MachineA multi-purpose beading & crimping rotary

deep throat machine, capable of forming many shapes on the sheet

metal edge.

TK 724 Combination Machine Specifications:

Tin Knocker TK Power Crimper BeaderWith a 13” throat and capacity of 18- gauge mild steel, this workhorse can perform most all beading and swaging functions. It is a beefy 3/4 HP machine, and made of solid, machined cast iron, mounted on a sturdy sheet metal cabinet. A two-pedal foot switch allow the operator to have two hands free at all times when changing direction of the rolls. An enlarged back gauge plate also facilitates handling of the part. Includes spacer collars for all operations except flanging. Rolls on this machine are interchangeable with the Roper Whitney Pexto 3617 rolls.

TK Power Crimper Beader Specifications:

Tin Knocker TK Manual Crimper BeaderCrimp and bead in one pass of the metal, 24 Ga. and lighter. Normally in stock in one of our warehouses. Crimp and bead in one pass of the metal, 24 Ga. and lighter. Comes with ogee bead & crimping tooling, depth gauge and C-Clamp base. This machine is great for manufacturing furnace pipe.

TK Manual Crimper Beader Specifications:

Tin Knocker Flangers & Flanging AttachmentsTin Knocker TK No. 16 Power Flanger A perfect partner for the TK 16-gauge Pittsburg

Roll Former

TK No. 16 Power Flanger Specifications:

Tin Knocker TK No. 20 Power FlangerThis power flanger has the “auto-guide” feature, which automatically controls the forming of a right-angle flange. It will contour and follow any edge, straight or curved. Using the convenient table slot, the operator merely turns up a starting edge, starts the material through the rolls and lets go. This machine comes with a stand.

*Includes Stand TK No. 20 Power Flanger Specifications:

Tin Knocker TK Manual FlangerPuts 7/32" flange on elbows and other radius fittings. Bench mounted, there is no gauge to set, and requires no special tools.

TK Manual Flanger Specifications:

Tin Knocker 20 & 24 Ga Flanging AttachmentAdd this option to turn up a 3/16 flange on straight or contoured sheet metal.

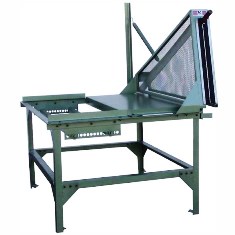

Tin Knocker Liner TableTin Knocker TK Liner TableThe Tin Knocker manual insulation cutter slits fiberglass insulation to length and width. Material is fed into the machine with a crank handle. The desired width is immediately cut with the adjustable slitter blade while the insulation is fed into the blade. The embedded scale makes for fast and accurate cutting. Once the material is at the desired length the operator pulls the handle, quickly and efficiently slitting the insulation to length with the crosscut blade. The result is a simple and easy way to make repeatable cuts to fiberglass insulation.

TK Liner Table Specifications: Features:

Tin Knocker NotchersTin Knocker TK Hydraulic Corner Notcher

TK Angle Iron Specifications:

TK Angle Iron Features:

Tin Knocker TK Angle Iron WorkerHere is versitility and multi-functionality!! The TK Angle Iron Worker consists of Angle Iron Shear, Angle Iron Notcher and Angle Iron Bender. Great for making sign frames, trailer frames, machine stands, or anything using angle iron. A 72” operating bar handle is furnished and fits all of the tools. TK Angle Iron Specifications:

Tin Knocker TK Edge NotcherThis rotary notcher is for round surface edges for collars and end caps. It is similar to the old Engel Model 750 Edge Notcher.

TK Edge Notcher Specifications:

Tin Knocker TK Drive Cleat NotcherThis tool notches drive cleats giving drives a rounded end for an easier installation. Notch drive cleats before or after they are formed. Easy to use with a spring loaded push handle. This tool easily mounts to any bench. TK Drive Cleat Notcher Specifications:

Tin Knocker TK 1655 Notcher - ManualA heavy versatile tool capable of not only notching to capacity but also shearing and piercing operations in lighter gauge. Of heavy cast iron and fabricated construction, this table top machine comes with front gauges and surface ground table. Stand is optional.

TK 1655 Manual Notcher Specifications:

Tin Knocker TK 1016 NotcherNotches up to 6 times faster than hand notching. This 5 headed gang notcher is a fast and easy way to notch sheet metal ducting, in preparation to receive bar, S Cleats and Drive Cleats…or other drive connections. QuickNotch allows you to gang-notch sheet metal hydraulically up to 600% faster than by hand, without layout or scribing. It’s the perfect tool for preparing bar, slip or “s” and drive connections.

TK 1016 Notcher Specifications:

Tin Knocker Plasma TablesTin Knocker TK Wizard 5 X 10 Plasma Table The Wizard plasma cutting system

was developed specifically for the HVAC contractor/fabricator.

It was developed specifically for the small to medium size

TK Wizard Cutting Table Features &

Specifications:

Tin Knocker PunchesTin Knocker TK 18 Station Turret PunchThe Tin Knocker TK 18 Station Hand Turret Punch is a fast, accurate and flexible method of punching holes in sheet metal in the shop. Priced at what you would expect to pay for a used (second hand) machine, this 18 station, 8-ton punch is built to last. The solid cast and machined C frame and precision machined and ground turret make for smooth effortless punching over the user’s lifetime.

TK 18 Hand Turret Punch Specifications:

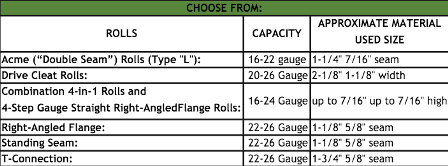

Tin Knocker Roll Forming MachinesTin Knocker TK T-D-P TDC Roll Former MachineTransverse Duct Connector Profile Roll Former Comes Standard

With: TDP Rolls, TDP Clip Rolls, TDP Clip Slitter & Feed

TK T-D-P Specifications:

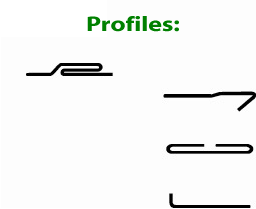

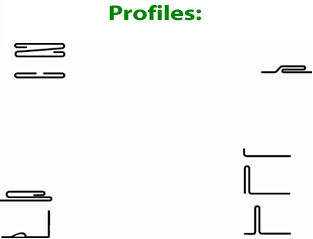

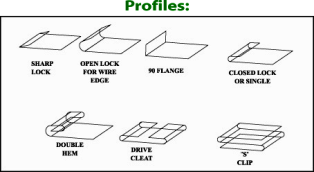

Tin Knocker TK 16 Ga Pitts Pittsburgh Roll Forming MachineThe 16 gauge Pittsburgh Lock machine comes loaded with 7 forming stations with 2 forming positions. One position forms the Pittsburgh Lock, while the outboard position has the ability of forming a number of other profiles, to include: Acme Pipe Lock, Drive Cleat or 4 in 1 rolls (3/16” Right Angle Flange, 7/16” Right Angle Flange, Standing Seam and T-Connection. You don’t pay extra for the choice of opposing rolls, either. You get your choice of rolls opposite the Pittsburgh rolls. Tk 16 Ga Pittsburgh Specifications:

Tin Knocker TK 20 Ga Pitts Pittsburgh Roll Forming Machine with Optional FlangerThis 5 station 20 Gauge Pittsburgh lock roll former is offered with choice of Drive Cleat or Acme rolls on the other outboard side. Powered by a 1 HP motor with V-belt drive

TK 20 Ga Pittsburgh Specifications: Tin Knocker TK 24 GA Pitts Pittsburgh Roll Forming Machine With Stand & Optional FlangerPortable rollformer for 24 gauge and lighter material. It is available with power flanging attachment and is perfect for field use. Includes an all steel stand. TK 24 Ga Pittsburgh Specifications:

Tin Knocker TK Fourplex S & Drive Roll Forming Machine W/ Slitter AttachmentThe Tin Knocker Fourplex is ANOTHER MACHINE THAT PAYS FOR ITSELF IN SAVINGS! Imagine being able to pick up scrap behind your shear and within seconds, turn that scrap into usable product. Imagine no more. Here is a machine that comes with two slitter rolls and four roll sets, two of which is your included choice. Outboard rolls can be selected from a list of available profiles (Pitts, Button Lock, Right Angle Flange, 4-in-1). HERE IS THE VALUE, value from scrap and labor savings, multi-functional service, speed and flexibility. The TK Fourplex comes with S & Drive Cleat down the center and choice of rolls for the outboard shafts. NO OTHER STANDARD ROLL FORMER HAS FASTER PAYBACK.

TK

Fourplex Specifications: Features:

Tin Knocker TK 20 Buttonlock Roll Forming MachineTin Knocker's 9 Station Button Lock Rollformer means no hammering over of edges. The Button Lock roll former comes with "male" tooling on one side and "female" on the opposing side. in Knocker’s 9 Station Button Lock Roll Former means no hammering over of edges and fast duct assembly. 220/3/60 Electrics, standard. A fast, effective way of marrying 20 to 26 gauge duct section

TK 20 Buttonlock Specifications:

Tin Knocker TK S & Drive Plus Cleat FormerThe TK S & Drive Plus roll former is a versatile machine of multi-functions. It slits the blanks to width and feeds either of the two roll roll sets. The machine comes standard with your choice of two sets of tooling. Most common examples: 20 Ga. Pittsburgh and 4-in-1 Rolls and Male & Female 20 Ga. Button Lock. It is fast, too. Many other roll sets to choose from… two sets included. The slitting feature allows you to quickly and easily turn scrap metal into usable product. TK S & Drive Plus Specifications:

Tin Knocker TK No. 24 Collar Maker MachineNotch, bead, crimp and roll complete round starting collars, 3" to 14" in diameter out of 24 to 30 gauge galvanized - in only one pass. Just cut to width and length or use scrap. This machine uses either 3" or 6" width blanks with simple movement of the crimp roll. TK No. 24 Collar Maker Specifications:

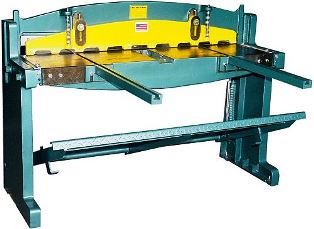

Tin Knocker ShearsTin Knocker TK 1652 Foot ShearThe Tin Knocker 1652 foot shear is easy to operate. Comes with 25" scaled back gauge. The Tin Knocker 1652 foot treadle operated squaring shear incorporates all those features to which you are accustomed, to include precise gauging and beefy hold downs for shearing accuracy. This shear is easy to operate and will give you many years of dependable service. Comes with 25" scaled back gauge.

TK 1652 Foot Shear Specifications:

Tin Knocker TK NO. 1 & TK No. 2 Hand ShearOur TK Hand Shears are versatile metal cutting tools. With these shears virtually any desired cut can be made with most metals. Both models are designed to be bench mounted. The throat less shears from Tin Knocker come in two capacities, 14ga & 10ga. These machines make awesome cutting tools. Both models use a unique shoulder design that allows you to turn the metal in any direction during the cut. These hand shears are set up for clean, burr free cuts. TK No. 1 Hand Shear Specifications: TK No. 2 Hand Shear Specifications:

Tin Knocker TK H1652 Hydraulic ShearThe Tin Knocker power squaring shear makes shearing light gauge metal easy. The design and features make shearing accurate and efficient. This shear can accommodate 52” sheet with a maximum capacity of 16-gauge mild steel. The hydraulically powered unit features fast and smooth shearing action, rear operated parallel rack and pinion back gauge, reversible 4 ft. squaring arm with embedded scale and 3 drop stop gauges. Also includes one shot lube system. No one offers a 52" x 16 gauge Hydraulic Shear with greater value. Pay less and get more!

INCLUDES: Front support arms, Parallel rack and pinion back gauge, 5ft squaring arm with drop stops.

Specifications:

Tin Knocker TK Jacketing ShearThis combination payoff cradle and hand shear cuts light gauge sheet metal, paper and thin plastic. *Scissor type with a hardened blade.

*Cuts galvanized or stainless jacketing up to

26-gauge, aluminum up to 22-gauge.

TK Jacketing Shear Specifications:

Tin Knocker TK 1014 Air ShearTry to find a comparable 10 ft. x 14 ga. Power Shear in terms of features and price! You won’t find it. This shear sets a new standard for value in a 10 ft. x 14 ga. Power Shear. It is loaded with truly usable, standard features.

TK 1014 Air Shear Specifications: Features:

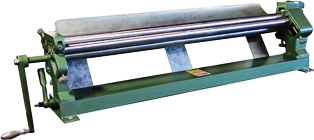

Tin Knocker Slip RollsTin Knocker TK 2236 Manual Slip RollTin Knocker rolls are among the strongest in the industry. Precision machined and ground from high carbon steel, these rolls come with wiring grooves, enclosed gear box, and slip roll lift lever. Stand is optional. *Shown With Optional Stand TK 2236 Slip Roll Specifications: Features:

Tin Knocker TK 2450 Manual Slip Roll The Tin Knocker 50” Slip

Roll is industrial strength. Precision machined and ground from

high carbon steel, these rolls come with wiring grooves, enclosed

gear box, and slip roll lift lever. Perfect for insulation contractors.

TK 2450 Slip Roll Features:

Tin Knocker SlittersTin Knocker TK 2024 & TK 1624 Slitters

*Shown With Optional Stand TK 2024 Slitter

Features: TK 1624 Slitter

Features:

Tin Knocker SpotweldersTin Knocker Model TK 1524 Foot Operated (Water Cooled) SpotwelderAt last, a Heavy Duty, Industrial Quality Spot Welder, at a Price that you can afford!

Features: Specifications: Return to the New Machinery Page Return to the Home Page

|

||||||||||||||

.jpg)