|

|||||||||||||||

Used Machinery Used

Air Compressors Used

Sheet Metal Brakes Used

Duct Beading Machine Used

HVAC Duct Insulation Pin Spotters Used

Pipe Equipment Used

Sheet Metal Rolls

|

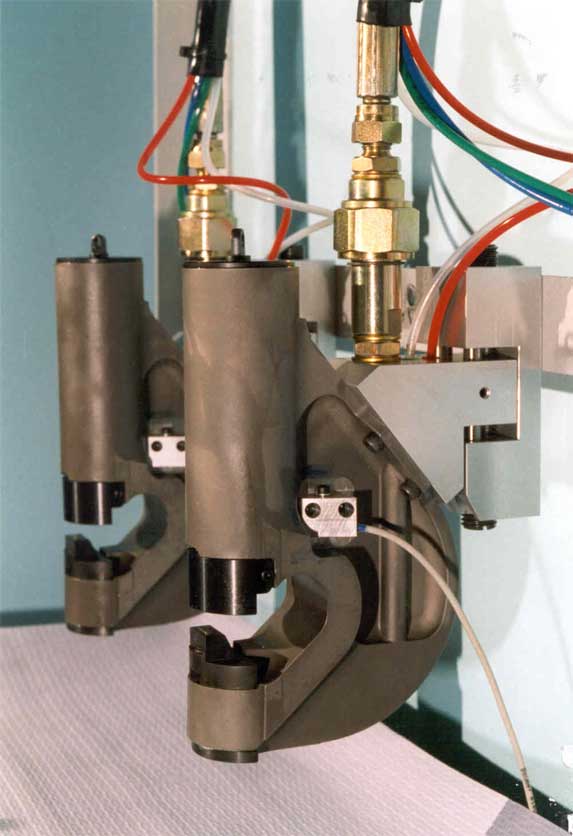

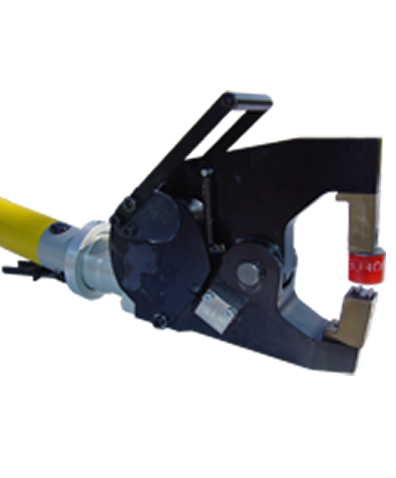

Clinching/Fastening SystemsClinching describes the forming of a Clinchlok joint. A Clinchlok joint is formed when the upper tooling squeezes the two ply of material joined between a punch and die. The strength of the Clinchlok joint and the life expectancy of the punch and die are both determined by the amount of squeeze. It is important to note that because the die is of a very special design, the Clinchlok is able to “mushroom”. Like the die, the punch in a Clinchlok joint is also of a special design that has a rounded edge, rather than a sharp edge like a normal punch. This rounded edge is known as the punch tip radius. To form a Clinchlok joint, neither the punch or die can be sharpened.

Return to the New Machinery Page Return to the Home Page

|

||||||||||||||

.jpg)